Gear fine forging products and automation production line series

Project progress:

1. The project team has broken through the technical bottleneck, and the passive sample is successfully tried using cold extrusion;

2. The project is declared in the "2021 Hubei Science and Technology Plan Project", won the quota of Xinzhou District and obtains a special subsidy of 500,000 yuan;

3, autonomous research and development of CNC servo fine forces for the project has been put into production, planning to complete the debugging in late December;

4. The development of the entire automation production line is planned to be completed before July 2022, and it is expected that the output value is 20 million yuan.

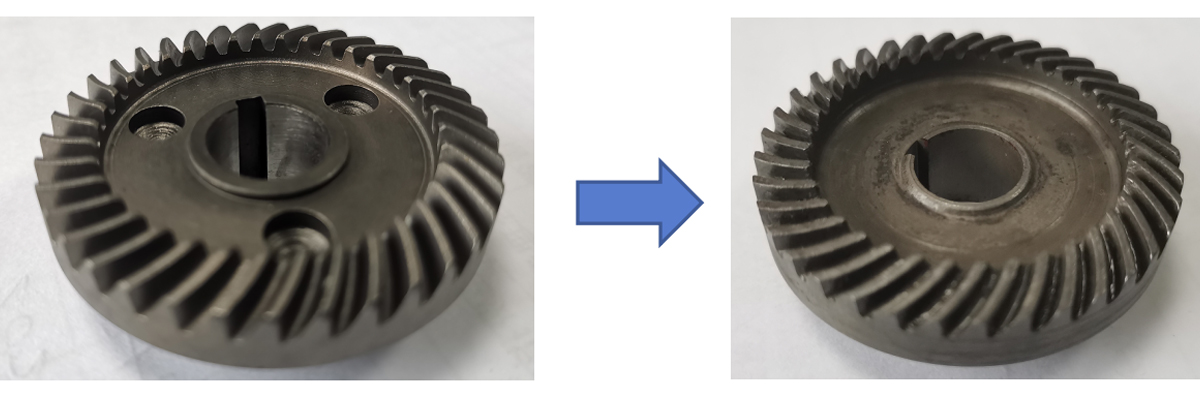

Sample 1 (Traditional Milling Technology) Sample 2 (gear fine forging process)

Spiral bevel gear precision forging process relative to traditional milling teeth process advantages:

☆1. The production efficiency is increased by 3-4 times;

☆2, the comprehensive performance of the gear is greatly improved;

☆3, the material utilization rate is higher;

☆4. The added value of product technology is higher.

Spiral bevel gear cold forging forming die

Related Products

Inquiry

Contact information

Message

Scan code

Tel: 0086-27-89620492

Fax: 0086-27-89620499

E-mail: hxfb@hxfb.com.cn

Address: Industrial Park, Yangluo Economic Development Zone, Xinzhou District, Wuhan, Hubei

Copyright: Wuhan Huaxia Fine Blanking Technology Co., Ltd Powered by www.300.cn 鄂ICP备11004789号-1